With conventional cooling lubrication systems cooling of the tool remains left to chance. Only with large amounts of media is trying to achieve decent results. There, the consumption of liquid is very high.

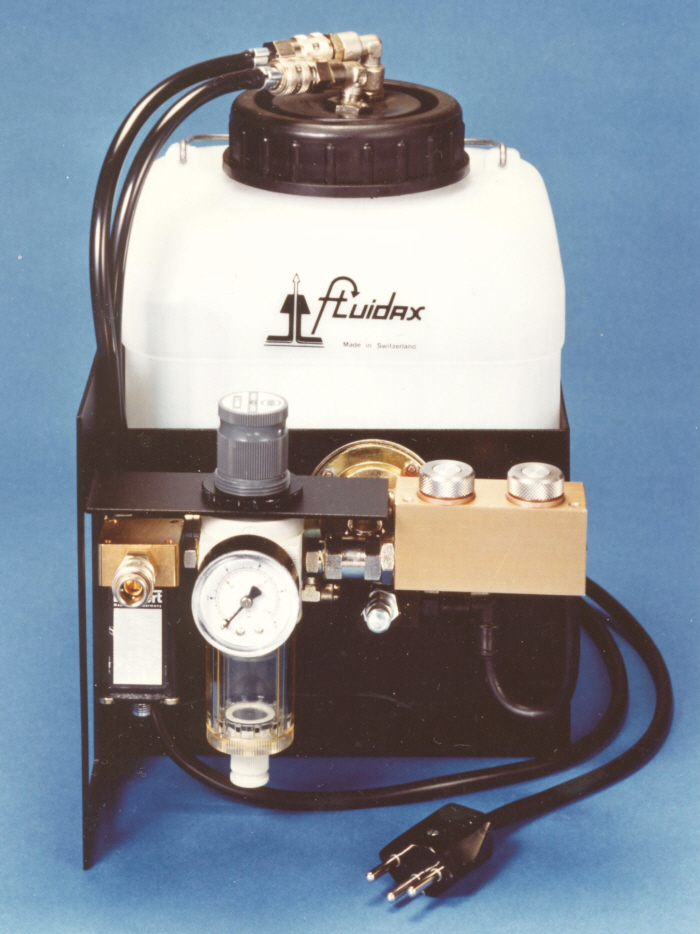

By using FLUIDAX low pressure control units you profit from:

- The specific cooling / lubrication of the cutting tool

- The massive extraction of heat at the reference point by constant low temperature of the spray

- The high exit velocity of the spray overcomes the air cushion of rotating tools

- The spray which is consisted with oxygen causes the formation of lubricating effect (oxide layers) on the tool

- The distribution of the sprayed liquid in small droplets is crucial for optimal heat dissipation (about 40-60 microns)

Suitable for water, fatty alcohols, emulsion, oils, rust and mold protection agents, graphite solutions, fragrances and dyes as well as other liquids upon request.

Get in touch with us and improve your process flow with FLUIDAX!