For copper-lubricated spindles, please comply with the following

- Most bearing damage is caused by impurities (debris, dirt, water, etc.); these can also interfere with the lubrication of the grease.

- Sealing air or air supplied externally to apply pressure must be absolutely clean. Water and oil must be separated from the air.

- The air supply must be filtered for impurities. A dehumidifier is a must!

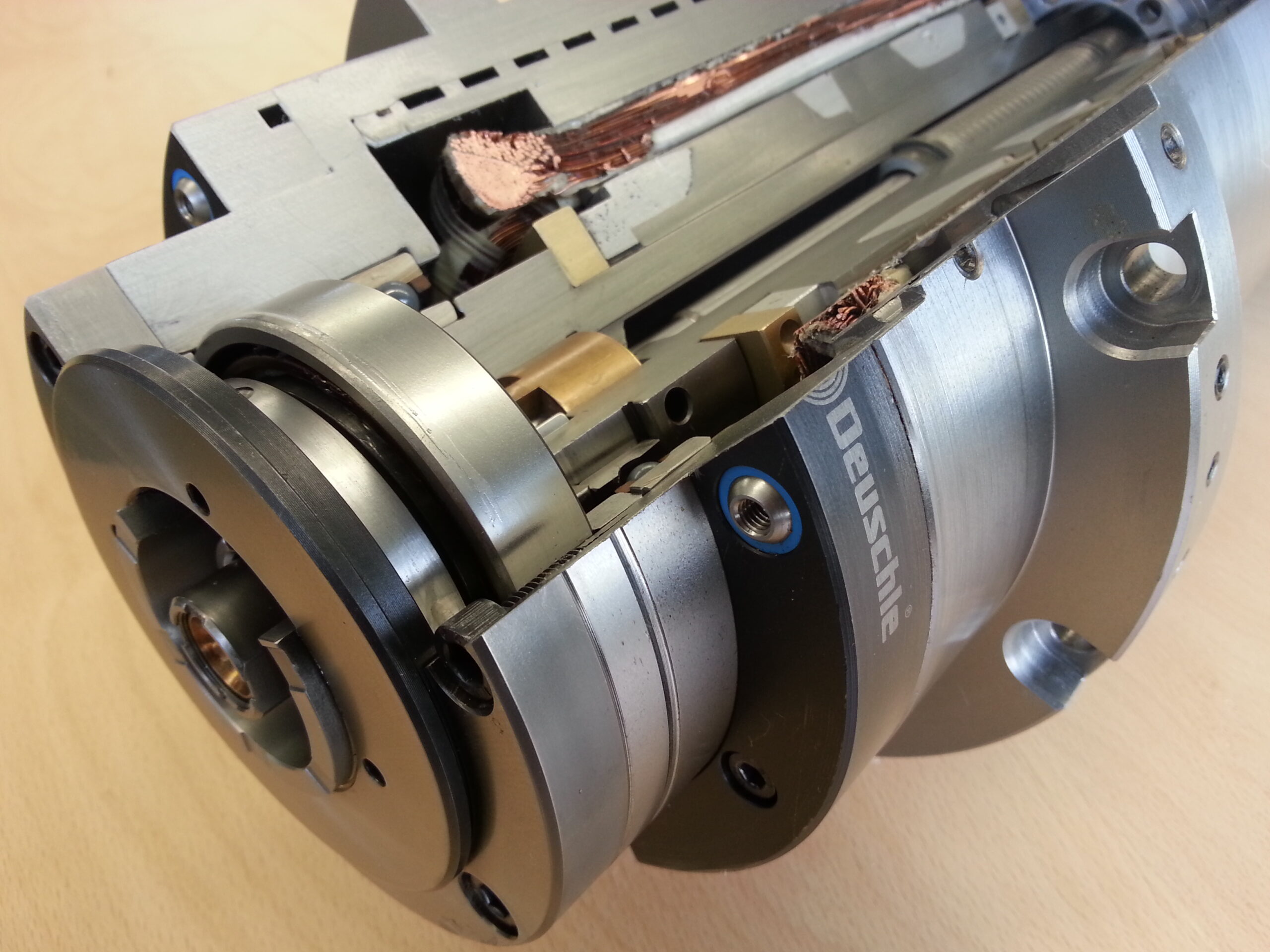

- If the copper-lubricated spindle has been stored for a long period of time, it should be preceded by 1-2 hours of low-speed operation. If the copper-lubricated spindle is stored for a long period of time, it should be run for 2-3 hours every 3 months in accordance with the commissioning instructions to prevent deformation of the copper.

- The bearing cage may make noise, but this is not a sign of bearing damage and will go away after a period of time when the spindle is running.

- Spindles that have not been in service for more than two years require disassembly and analysis to exchange for new copper. If so, please contact HQ.