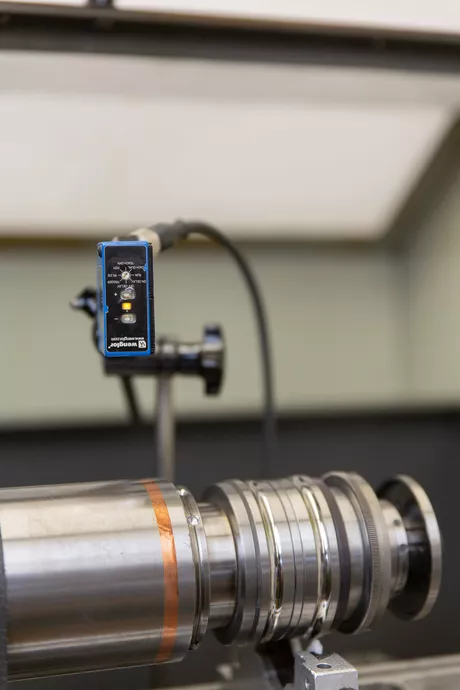

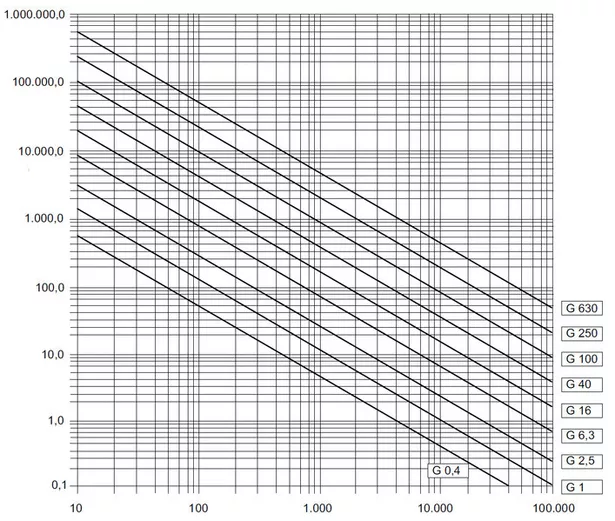

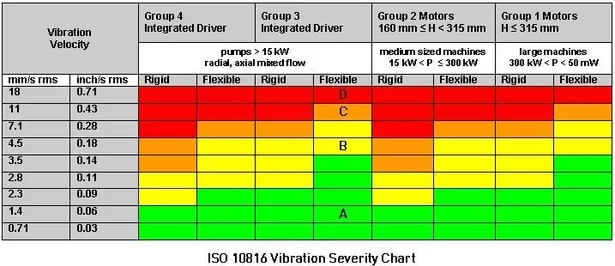

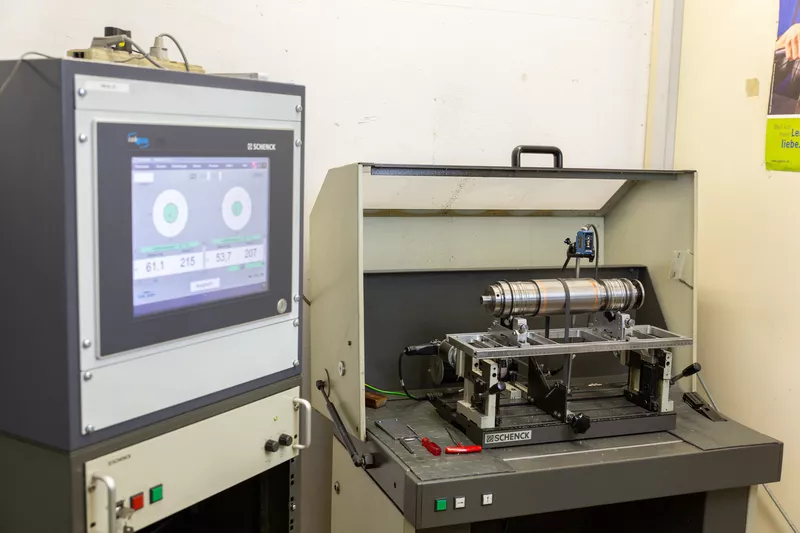

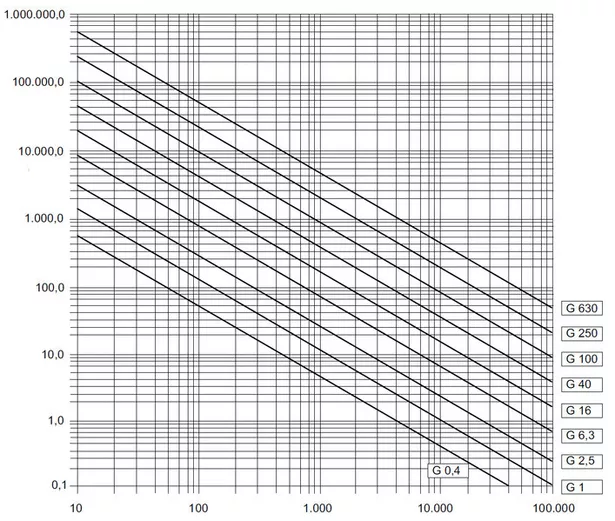

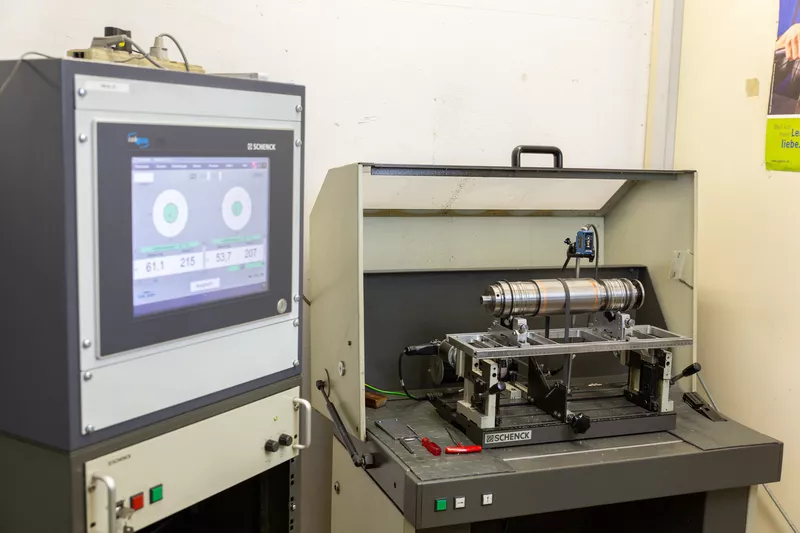

All important components of a spindle system require balancing. All rotating spindles for milling, grinding, etc., as well as small or high-precision rotors and rotors that rotate at tens of thousands of revolutions per minute, require precise balancing. In such cases, you can experience the true value of your spindles by using a balancing system with a permissible residual imbalance of micrograms (μg). To achieve these quality standards, you need a highly qualified and expert partner in this field. Precision balancing is a task that requires perfect interaction between man and machine. The engineers at Deutsche Schule not only know the relevant balancing processes, but also know how to optimally use the advanced technology offered by modern balancing systems, thanks to their extensive experience. Here is an example of the cumulative tolerances of all important components of a spindle system: Balance quality of spindle/drive + Balance quality of tool holder + Balance quality of tool = Final cumulative tolerance (must be less than G2.5 for a long operating life of the spindle).